Rudolf Diesel developed the engine technology that bears his name in the late 19th Century. Since then, diesel engines have become popular for their reliable and efficient operation and long life. Gasoline and diesel engines share a basic structure and set of operating principles, but higher compression ratios and diesel fuel’s higher energy capacity make diesel engines more efficient than their gas counterparts. This advantage is most significant in terms of torque output and at low RPMs, which makes diesel better suited to heavy-duty applications like farm equipment and trucks. Gas engines are better suited to vehicles where acceleration is more important, like sports cars.

Most modern diesel engines employ turbochargers to help close this gap, even larger ones like the 6.6 liter Duramax diesel that Chevrolet developed in partnership with Isuzu. The version of that engine that powers the 2024 Chevy Silverado is capable of 470 horsepower and an astonishing 975 pound-feet of torque. In comparison, GM’s L8T 6.6 liter gas-powered V8 makes 404 horsepower and 464 pound-feet of torque.

It’s not just the Duramax that can yank tree stumps with ease; the Cummins 6.7 liter turbodiesel found in many Ram trucks can generate as much as 420 horsepower and 1,075 pound-feet of torque. Despite those whopping power numbers, truck owners are always looking to get more out of their diesel engines. SlashGear is here with a few simple tips to show you how to do just that.

Upgrade the air intake

All internal combustion engines rely on an outside supply of air to aid combustion, but with diesel engines, increasing the airflow to the intake manifold can dramatically improve performance. Replacing your diesel engine’s stock air filter with a cold air intake like the Banks Ram Air can increase airflow to the engine by more than 50%. On most gas engines, installing a cold air intake does little to improve performance or fuel efficiency, but in a diesel engine, increasing the supply of air to the engine can have a dramatic effect on how well the engine performs.

This is because gas engines rely on a carburetor or fuel injection to mix gas and air, and a spark plug ignites that mixture, while diesel engines use rapid air compression to initiate combustion. Cold air holds more oxygen per unit of volume than warm air, making it more volatile. The air filters that come with many cold air intakes are often of better quality than the original equipment and can sometimes be cleaned and reinstalled in lieu of replacement.

Upgrade the exhaust system

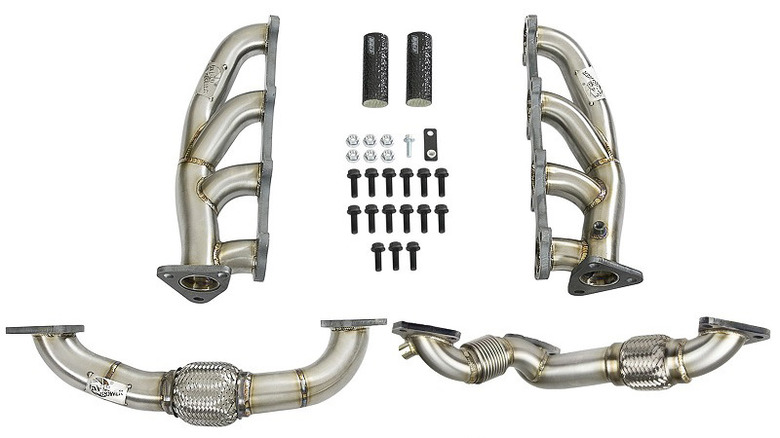

Another way to get more horsepower and fuel efficiency out of your diesel engine is to increase the airflow rate from the engine using an aftermarket exhaust system. This system begins at the exhaust manifold and ends at the end of the tailpipe, and sometimes, simply using larger diameter tubing from the flange back will provide a significant boost. You can also install a manifold with larger ports or a different routing from the stock system or do both. You’ll get the most dramatic increase in horsepower and fuel efficiency by replacing the manifold with exhaust headers.

Stock manifolds are designed to take up as little space as possible and channel the exhaust from all of an engine’s cylinders into a single point just ahead of the flange. Headers have individual tubes for each cylinder’s exhaust port, allowing gases to flow freely to the muffler and tailpipe. Stainless steel or titanium headers will also weigh less than cast iron manifolds, and weight savings equals fuel savings.

Most muffler shops will be able to custom-weld a set of exhaust headers to your truck, and there are plenty of bolt-on aftermarket options out there as well.

Clean or replace your DPF

The exhaust systems in modern diesel vehicles include a DPF or diesel particulate filter. This cylindrical or oval-shaped device is mounted inline near the tailpipe and traps soot, smoke, and other environmental contaminants. It becomes clogged over time and will restrict airflow through your exhaust system. Just like expanding the capacity of the system increases horsepower and fuel efficiency, keeping your DPF clean and replacing it when it becomes clogged is critical to maximizing your diesel truck’s performance.

Use a liquid DPF cleaner regularly to clear out small deposits, and make sure you swap out your DPF at the interval recommended in your owner’s manual. Some DPF cleaners are added to the fuel tank when filling up; others can be poured directly into the intake where the air filter is mounted. You can also have your DPF cleaned at a shop using compressed air.

Replacing your DPF with a straight pipe or making other modifications might be tempting, but altering or deleting emissions control equipment is illegal and dangerous to the environment. You can get a BullyDog emissions-compliant high-flow DPF from vendors like Desert Rat Off-Road or AFA Motors; BullyDog claims its DPF units will increase exhaust flow by more than 20%.

Upgrade the turbocharger

As noted earlier, most modern diesel engines use a turbocharger to help boost acceleration and fuel economy. An easy way to boost the performance of a turbodiesel engine is to replace the stock turbocharger with a more powerful aftermarket one. Aurora Turbo Systems and Banks Power make turbo upgrades for various popular diesel motors, including Duramax, Cummins, and Ford Powerstroke engines. Most turbo upgrades bolt easily in place of the stock unit and work seamlessly with your engine management computer and sensors. Upgrading your turbocharger is an easy, emissions-compliant way to dramatically improve engine output and fuel economy.

For example, Aurora’s ATS 5000 fits Cummins 5.9 liter engines and supplies up to 70 PSI of boost for a power output of more than 850 horsepower. Aurora also sells a line of calibration and diagnostic computers designed to help you get the most out of any turbocharger upgrade.

Upgrade the fuel injectors

Just as increasing the supply of air to a diesel engine will make the combustion of fuel produce more energy, so too will introducing more fuel into each cylinder via high-flow fuel injectors. This easy upgrade can increase fuel flow by as much as 250%, but upgrading your injectors requires additional engine modifications, some of which we have already addressed.

More fuel means you’ll need more air to combust the fuel properly, so a high-capacity turbocharger and/or upgraded air intake should be installed along with high-performance fuel injectors. Depending on how different the replacement turbo’s spool rate is from the stock one, you might also have to replace your existing torque converter with one that matches the new spool rate.

You’ll need to ensure your exhaust system can handle the added power your engine is producing and be prepared to spend more money at the pump. Your engine’s computer may also have to be recalibrated or reprogrammed to adjust to its new fuel flow demands. By the time you get your high-capacity injectors integrated properly, this path may end up being a complicated and expensive one.